MO4 Tender

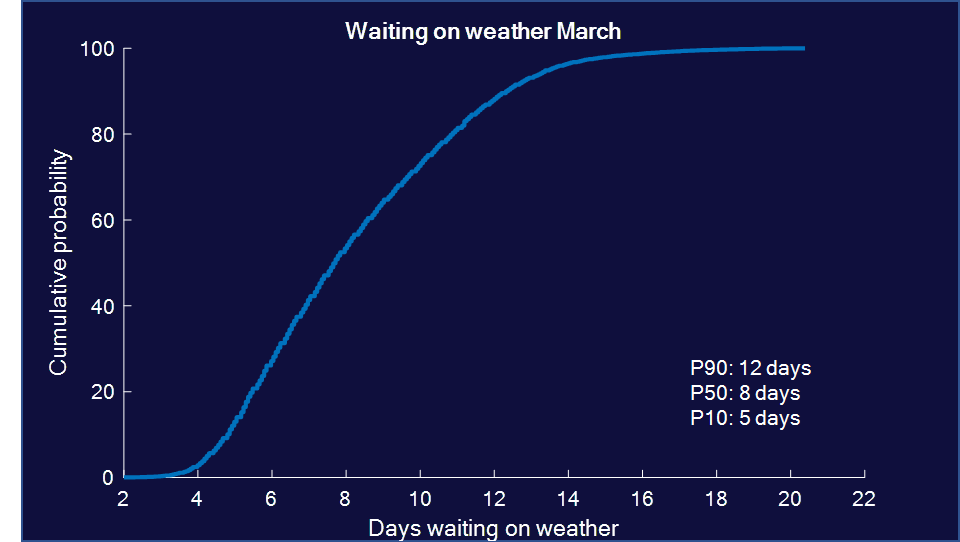

When tendering on a project, there is always little time and budget. However, it is a key moment for the financial success of a project. This means you want to get a good estimate of the operational costs, without spending too much time and effort. This is precisely what MO4 Tender offers.

MO4 Tender is the most accurate method to determine the operational performance of an offshore operation. Based on historical weather data an offshore operation is simulated as if the vessel was in the field. The type of operation can vary from personnel transfer, crane lifts, jacking, and much more. The operation is then virtually started every hour of the dataset and the weather downtime is determined. Key data on operational performance of assets can be obtained and optimized. The strategies with respect to execution period, hardware investments and vessel allocation can be verified and optimized. Making your tender more competitive and your project more profitable.

MO4 Tender simulates an operation to determine the weather downtime

The figure above present an instant from one of our more complex heavy lift operations. The analyses has supported a new methodology that has enabled a significantly reduced duration for the project.

Engineering Services

Mocean Offshore is a specialized marine engineering consultant with extensive experience in conventional systems and an industry driver for the development of maritime innovations. We apply solid numerical methods to a practical approach to enable fully optimized projects in either decommissioning analyses, mooring design, heavy lift analyses, vessel motion studies and subsea analysis.

Mocean has always been about digging (or diving) deeper, knowing what is going on and truly understanding the physics or human processes involved in either offshore projects or marine innovations. This has always enabled us to balance between the purely scientific research institutes and every-day (marine-) engineering companies. In between is our natural habitat where we can offer our clients the best of both worlds

Specifically for the decommissioning projects we have been able to open new windows of opportunity by applying solid numerical analyses. Our support in heavy lift and transport methods and analyses in over 15 decommissioned structures has enabled us to be very fast in our deliverables while ensuring that we meet the requirements of all our clients project stakeholders. Understanding what the different stakeholder require or want to see leads to a smooth and swift project execution and prevents hick-ups and engineering work being redone. All with one focus, ensuring a cost efficient an safe project execution from engineering till delivery.

MO4 Onboard

MO4 provides an onboard system for workability forecasting and monitoring. Offshore operations are limited by weather: waves, wind, current, visibility and much more. All these influences greatly affect the performance of the marine platform. Further, there are many stakeholders present: (sub)contractors, clients, marine warranty surveyor, engineers, and much more. This makes the decision-making process related to weather complex and inaccurate. MO4 aims to solve this by collecting and processing all the data in one single screen and presenting it in an intuitive way.

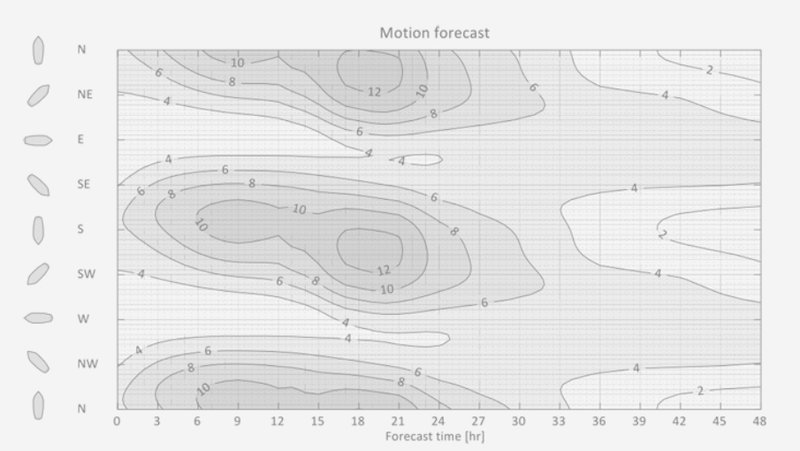

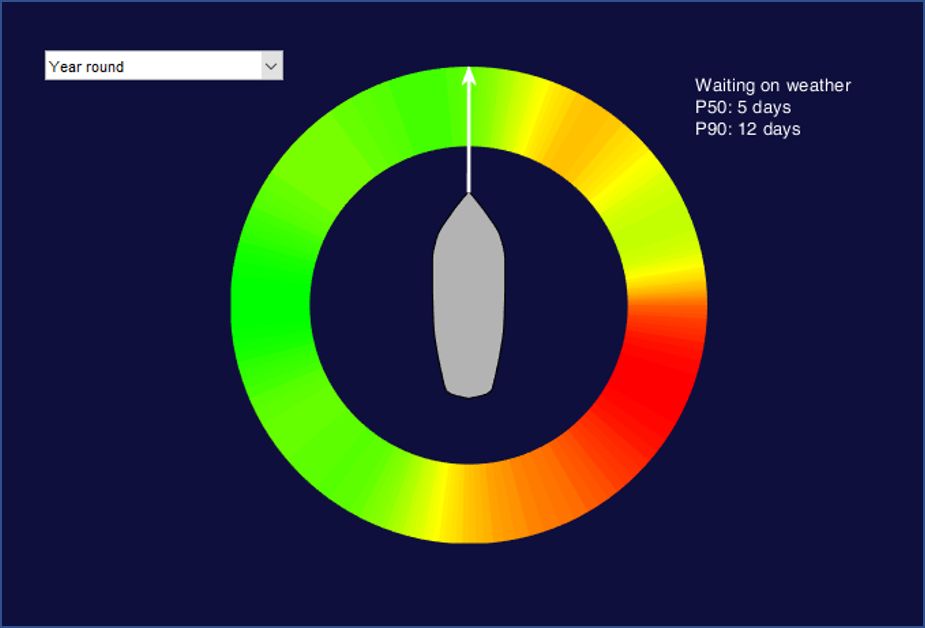

MO4 uses a state-of-the-art ship motion code combined with a detailed weather forecast, to generate a forecast of the ship motions of an unrivalled quality. This is combined with other relevant limits, such as current for working with ROVs, or the capability of a dynamic positioning system. The forecasted motions are presented in a simple way, to aid the crew of the vessel to make decisions based on the best available data. Motion sensors are used to provide confidence in the forecasts and real time insight into the vessel’s motions. A change in heading of offshore operations: from limits on the sea state to limits on the actual relevant motions.

Common paradigm in the offshore industry is to limit operations by significant wave height. This is a waste of vessel capability. The response of a ship is much more reliant on wave periods and relative heading of the vessel to the waves. Moreover, this paradigm can also lead to unsafe situations. MO4 is capable of measuring and forecasting motions that the vessel will encounter. Comparing these various motions to the respective criteria enables to investigate how close the operation is to its limits. Further, it enables users to find the optimal weather window and heading.

Measuring is knowing and the vessel is the best sensor in the field. Not only is a motion sensor more accurate than a wave rider buoy, the trends in the ship motions are more relevant to the operation than the trend in weather. MO4 presents this data so the user can see if the motions are increasing, decreasing or remaining steady.

Example of an actual sea state (energy over compass heading and wave period)

Indication of interface

Call to action:jelte@mocean-offshore.com

Website: www.mocean-offshore.com