Company Insight

Sponsored by Wanner Engineering

Advantages of Seal-less Pumps in Oil and Gas Production

Positive displacement pumps employing seal-less design technology lower the cost of ownership, reduce maintenance needs, and provide a longer service life than conventional plunger pumps. Based on its Hydra-Cell seal-less pumps introduced in 1973, Wanner Engineering is now offering higher capacity models for oil and gas production.

Scroll down to read more

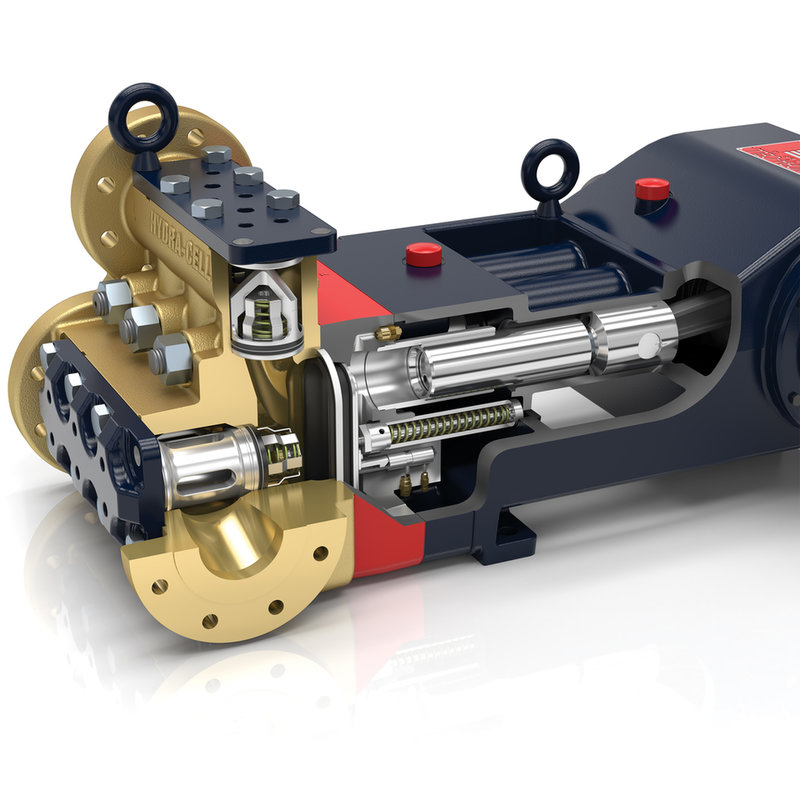

The seal-less design of a Hydra-Cell positive displacement pump (T100 shown) separates the hydraulic (power) end from the fluid (process) end. There are no dynamic seals, cups or packing to leak, wear or replace, and volatile organic compounds are fully contained.

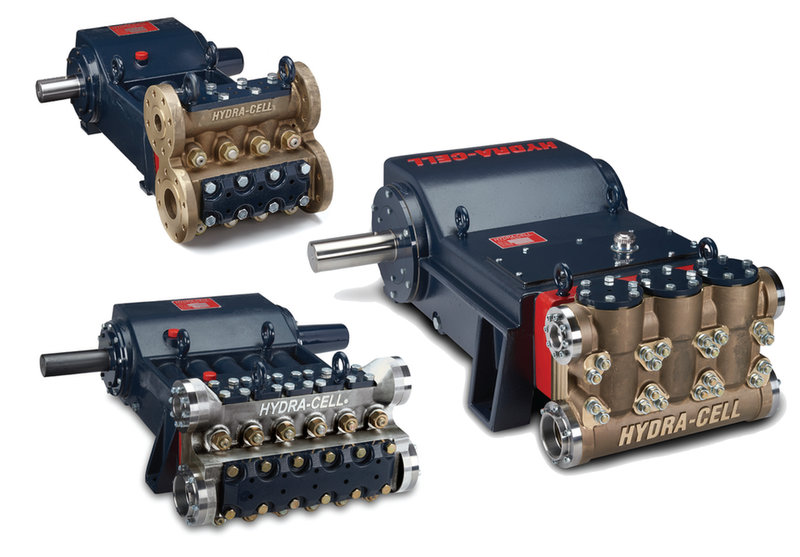

Hydra-Cell Seal-less Pumps are available in the T100 Series triplex, Q155 Series quintuplex, and T200 Series triplex models.

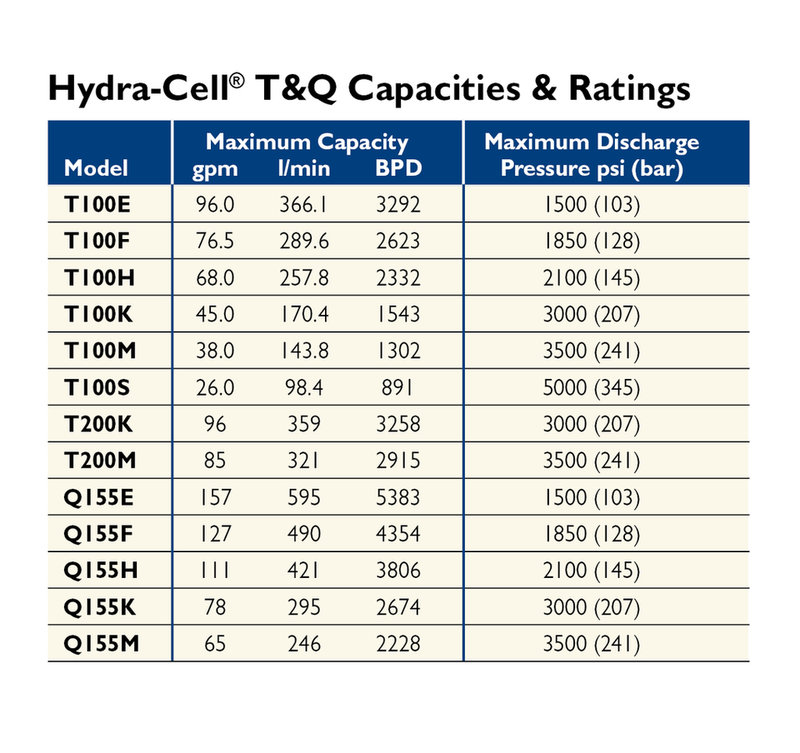

Flow capacities and pressure ratings for the Hydra-Cell individual model T & Q Series pumps.

Wanner Engineering continued R&D into larger models, and in 2010, unveiled a “T Series” pump that earned a “Spotlight on New Technology” award at the Offshore Technology Conference.

In offshore oil exploration and drilling—as with almost every other industry—downtime is money down the drain. When a company is routinely pumping thousands of gallons of oil, an unplanned break in production because of pump failure or system interruption can be costly.

Seal-less pump technology delivers several advantages in the oil and gas industry over conventional packed plunger pumps and horizontal centrifugal pumps.

For example, salt water and the contaminants it contains are corrosive. When carried through pipes at high pressure, they can erode seals, causing them to leak, clog, or fail. Conversely, if pipes run dry, the packing can dry out and crack, clog, or leak.

Most complex pumps have an open plunger, so whatever is sent through, such as saltwater, will leak through the packing. Furthermore, with standard metal rod pumps, metal-on-metal grating causes wear and tear. Unless there is frequent maintenance and upkeep, it can lead to breakage.

Origin and Development of Hydra-Cell Seal-less Pumping Technology

In the burgeoning commercial car wash industry of the early 1970s, special pumps were needed to provide high-pressure spraying as well as handle the dirty water drained from the pressure wash—water that typically contained abrasives, particulates, oil, and other contaminates.

William Wanner, Sr. of Minneapolis, Minnesota hit upon an idea for a positive displacement pump with hydraulically-balanced diaphragms that featured a unique seal-less design. His patented “Hydra-Cell” proved ideal for handling abrasives in the dirty water draining from car washes, and he soon founded Wanner Engineering in downtown Minneapolis.

Not only was Hydra-Cell a success in the car wash industry, its seal-less pumping technology proved an excellent choice in the oil and gas industry, as well as for many other processing industries, and as an OEM-specified component of integrated pumping systems.

The original Hydra-Cell line included a pump model with a flow capacity of 36.5 gpm (138 l/min). Although it was widely used for oil and gas applications, Wanner Engineering continued R&D into larger models, and in 2010, unveiled a “T Series” pump that earned a “Spotlight on New Technology” award at the Offshore Technology Conference (OTC).

Comparing the Seal-less Design to Plunger and Centrifugal Pumps

The Hydra-Cell seal-less pump design differs from plunger pumps in critical ways. They feature a unique, patented technology that utilizes a hydraulically-balanced, multiple-diaphragm design, in which the hydraulic end is separated from the fluid end. This keeps the pumped liquid 100 percent contained and eliminates leakages, cleanup and disposal costs commonly associated with packed plunger pumps.

The innovative design also eliminates the need for external lubrication and maintenance. Since Hydra-Cell is packing-free, there are no plunger wear problems associated with packing. As a result, Hydra-Cell can be used instead of horizontal centrifugal pumps or packed plunger pumps in oil and gas applications.

Benefits of Hydra-Cell Seal-less Pumps

- No leak path potential because the seal-less design separates the power end from the process end.

- Elimination of hazardous volatile organic compounds (VOC) emissions.

- Reduced cleanup and disposal costs associated with packed pump leakage.

- Hydraulically-balanced diaphragms handle high pressure with low stress.

- Multiple-diaphragm design delivers linear, virtually pulse-free flow, often without the need for expensive pulsation dampeners.

- Operates even when a suction line is becomes blocked or is closed because Hydra-Cell has the ability to run dry indefinitely without damage to the pump.

- Abrasives particles up to 800 microns in size can pass through the pump.

- No special requirement for positive inlet pressure because low net positive suction head requirements (NPSHr) allow for operation with a vacuum condition on the suction.

- Reduced energy costs compared to other types of pumps.

- Compact design and a double-ended shaft provide flexibility for installation options.

- Rugged construction contributes to a long service life with minimal maintenance.

These performance features contribute to a low cost of ownership, reduced maintenance and a long service life. The technology also can be used in oil and gas production for refining, pipeline transfer, and artificial lift.

Continued Development

The award-winning Hydra-Cell pump first presented at OTC in 2010 had a flow capacity of 45 gpm (170 l/min) and was soon joined by another model that could deliver up to 96 gpm (366.1 l/min). Today, the full scope of Hydra-Cell T100 and T200 Series triplex pumps, and Q155 Series quintuplex pumps range from 26 to 157 gpm (98.4 to 595 l/min) or up to 5383 BPD. Maximum discharge pressure ratings run from 1500 to 5000 psi (103 to 345 bar) depending on the model.

Contact Information

World Headquarters & Manufacturing

1204 Chesnut Avenue,

Minneapolis, MN 55403 USA

Tel: (612) 332-5681

Fax: (612) 332-6937

Toll: Free Fax (USA only) (800) 332-6812

Email: sales@wannereng.com

Web: www.hydra-cell.com

Back to top ▲