Sponsored by AAF

Company Insight

Sponsored by AAF

Performance Enhancement Solutions for Gas Turbines

What we do

At AAF, our years of experience underpin our expertise, our mission is to provide best in class service and support throughout the lifecycle of your plant. We’ve executed thousands of projects, delivering gas turbine auxiliary equipment, for small to large machines and to all of the major original equipment manufacturers.

Our product portfolio has allowed us to succeed in executing thousands of projects in some of the most demanding environments around the world; from sub-zero Arctic, to offshore marine and remote sandstorm deserts. In all cases the measured evolution of our gas turbine filters and other products has proven to ensure reliable performance for operators.

Typical applications:

- Urban / Industrial

- Coastal

- Marine

- Tropical

- Desert

- Artic

The value of filtration

From moisture removal and pre-filtration to cartridge and panel pak filters in high dust load environments, regardless of your filtration requirement if it is for a gas turbine AAF can help. All of our products add value and we focus on product innovation. This is very evident in the (H)EPA filtration market where the added value helps gas turbines realise greater power, increase efficiency and extend time between water washes. Right now, AAF (H)EPA filters are hard at work supplying clean air at stable differential pressure, extending engine life and increasing reliability to gas turbines around the world.

Increase machine availability

The advanced filtration of AAF (H)EPA filters help engine cores remain in close to new condition during operation. As a result, cycles between on or offline cleaning can exceed 8,000 hours. More time online means greater productivity.

Recover lost power

With an initial filtration efficiency of 99.5% or greater at the smallest penetrating particle size, AAF (H)EPA filters help maintain gas compressor cleanliness by recovering 6% of the power output normally lost to engine fouling in none power loss megawatt hours (Mw/hrs).

Enhance fuel efficiency

Today’s modern gas turbines have incredibly tight tolerances and critical profiles for maximum efficiency. AAF’s advanced filtration removes airborne pollution that can foul the engine compressor stator and rotor blades, helping gas turbines run with like-new efficiency even after extensive operation.

Extend engine life

With AAF (H)EPA technology, operators can enjoy substantially longer component life and engine reliability. The outstanding protection against salt, hydrocarbons, water and other airborne particles ensures complete peace of mind.

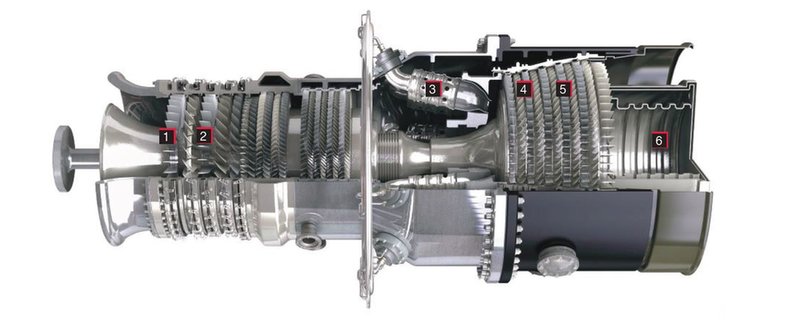

Maintain a clean and healthy engine

Maintain a clean and healthy engine

1. Eliminate compressor fouling

2. Eliminate or reduce the need for compressor washing

3. Increase fuel efficiency

4. Extend lifetime of engine components

5. Cooling ports clear of blockage

6. Constant power output

Gas Turbine Equipment

AAF’s experience in gas turbine equipment has supported its development into one of the leading and most diverse suppliers within the gas turbine auxiliary equipment field. This includes working with all of the world’s leading OEMs providing filtration systems, exhaust systems, ventilation and acoustic systems. AAF also provide other supporting products including heating and cooling solutions.

AAF’s high performing products are designed to meet the extreme conditions found in any gas turbine package. Our aim is to ensure greater gas turbine availability, a higher constant power output, an increase in engine component life, lower operating costs, reduced heat rate and an increase in fuel efficiency.

Gas Turbine Services

Gas turbine air intake, exhaust, ventilation and acoustic systems are vital components, which when maintained operate to protect gas turbines. Equipment of this importance requires the right calibre of support, with years of experience and a highly qualified global support team, AAF will work with you to fulfil all of your maintenance requirements.

Starting with understanding your past and current plant performance, as well as ambitions for improvement, AAF takes ownership from inlet to exhaust to guarantee a dependable air quality hour after hour. AAF Service Engineers ensure gas turbine auxiliary equipment is kept within optimum working conditions, including a comprehensive upgrade and modification service.

Contact Information

AAF

SUITE 20 PLUMRIDGE HOUSE

36 AGNES ST

FORTITUDE VALLEY

BRISBANE QLD 4006

E gasturbinesolutions@aafgb.com

W www.aafintl.com

+44 (0) 1670 713 477

Back to top ▲