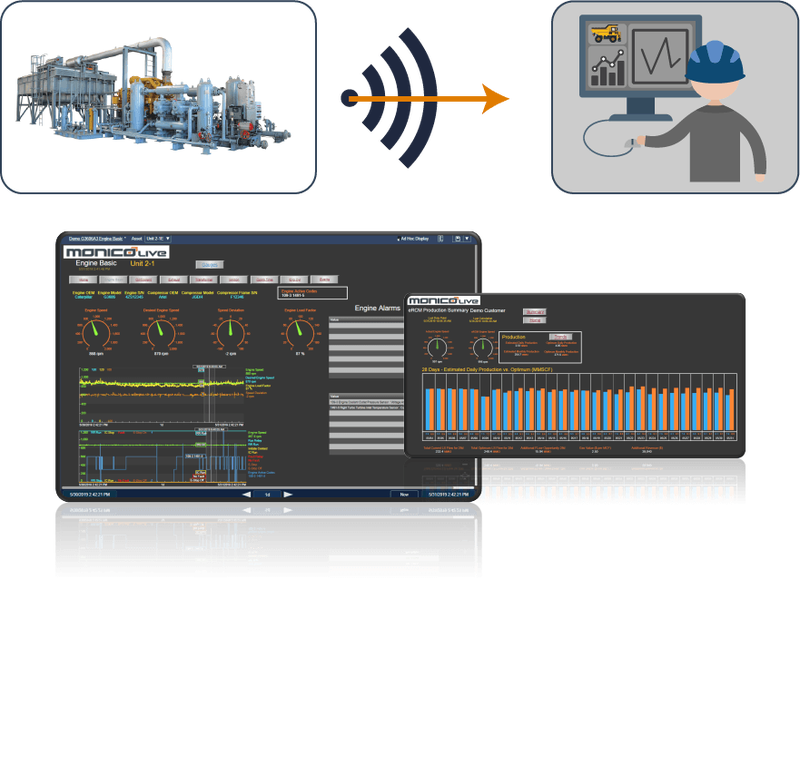

mGuard® CompressorWatch™ is remote condition monitoring for your reciprocating gas compressors. Providing service managers, technicians and maintenance crews with a powerful tool that is specifically designed to provide valuable insight into the performance and health status of their compression station packages (i.e., drivers and ancillary equipment).

Monico’s mGuard CompressorWatch includes real-time predictive analytics that run unattended 24/7/365 as data streams in from the asset(s).

Systems and Components being analyzed include:

Emissions

Engine & Compressor Components

Engine & Compressor Sensors

Engine Performance

Compressor Valve Failures

Equipment KPIs (e.g., Reliability)

Jacket Water Cooling Systems

Auxiliary Cooling Systems

Air Intake Systems

Ignition Systems

Lubrication Systems

Exhaust Systems

Air/Fuel Ratio Systems

mGuard® CompressorWatch™ helps to provide:

More time to schedule and prepare for needed repairs

Useful analysis that aids in determining the severity of a failure

Improved Mean Time to Repair (MTTR)

Improved Reliability, Utilization and Mean Time Between Outage (MTBO)

Increased production and reduced unscheduled downtime

mGuard® CompressorWatch™

is remote condition monitoring for your reciprocating gas compressors. Providing service managers, technicians and maintenance crews with a powerful tool that is specifically designed to provide valuable insight into the performance and health status of their compression station packages (i.e., drivers and ancillary equipment).

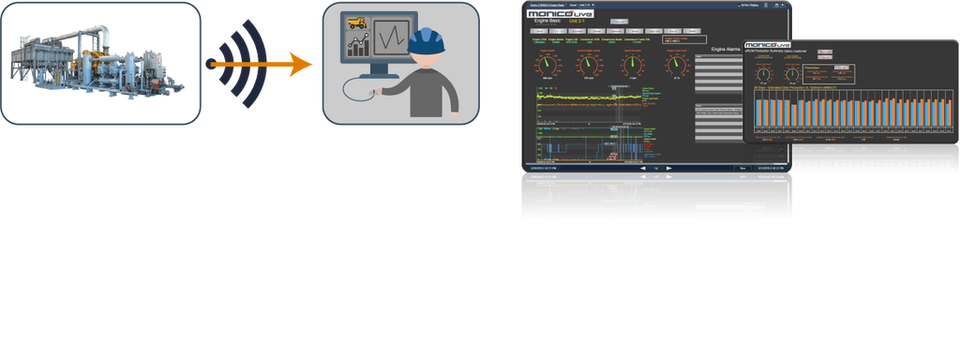

mGuard® CompressorWatch™ is remote condition monitoring for your reciprocating gas compressors. Providing service managers, technicians and maintenance crews with a powerful tool that is

specifically designed to provide valuable insight into the performance and health status of their compression station packages (i.e., drivers and ancillary equipment).

Monico’s mGuard CompressorWatch includes real-time predictive analytics that run unattended 24/7/365 as data streams in from the asset(s).

Systems and Components being analyzed include:

Emissions

Engine & Compressor Components

Engine & Compressor Sensors

Engine Performance

Compressor Valve Failures

Equipment KPIs (e.g., Reliability)

Jacket Water Cooling Systems

Auxiliary Cooling Systems

Air Intake Systems

Ignition Systems

Lubrication Systems

Exhaust Systems

Air/Fuel Ratio Systems

Systems and Components being analyzed include:

Emissions

Engine & Compressor Components

Engine & Compressor Sensors

Engine Performance

Compressor Valve Failures

Equipment KPIs (e.g., Reliability)

Jacket Water Cooling Systems

Auxiliary Cooling Systems

Air Intake Systems

Ignition Systems

Lubrication Systems

Exhaust Systems

Air/Fuel Ratio Systems

mGuard® CompressorWatch™ helps to provide:

More time to schedule and prepare for needed repairs

Useful analysis that aids in determining the severity of a failure

Improved Mean Time to Repair (MTTR)

Improved Reliability, Utilization and Mean Time Between Outage (MTBO)

Increased production and reduced unscheduled downtime

mGuard® CompressorWatch™

is powered by mCore®SDR and built on the MonicoLive™ Remote Monitoring Solution

Powered by mCore®SDR

built on MonicoLive™ Remote Monitoring

Industrial Data Acquisition

With a Monico mCore®SDR you can:

• Capture machinery and equipment data remotely

• Convert protocols (e.g., CAT® Data Link and J1939)

• Buffer data

• Process analytics (at the edge)

• Securely transmit data

• Integrate mobile equipment data with OSIsoft® PI

• Save on data bandwidth usage with exception reporting

For more information

Click Here

Industrial Data Acquisition

With a Monico mCore®SDR you can:

• Capture machinery and equipment data remotely

• Convert protocols (e.g., CAT® Data Link and J1939)

• Buffer data

• Process analytics (at the edge)

• Securely transmit data

• Integrate mobile equipment data with OSIsoft® PI

• Save on data bandwidth usage with exception reporting

For more information

Click Here

Remote Condition Monitoring

Storage of Data

Visualize Data

Cloud Analytics

Alerts & Notifications

Trending of Data

For more information

Click Here

mGuard® CompressorWatch™ collects real-time streaming data from the compression station assets; including the engine ECM, Package Controller and other external sensors.

mGuard® CompressorWatch™

collects real-time streaming data from the compression station assets; including the engine ECM, Package Controller and other external sensors.

mCore®SDR is the industrial data acquisition device that is collecting data from connected assets. The data is then sent to the MonicoLive™ Cloud environment where mGuard® CompressorWatch™ is analyzing data in real-time

For more information

Click Here

The Monico Advantage

At Monico our job isn’t done until your data is going to where it needs to be, in the format it needs to be in. We don’t just sell you a gateway, hand you a manual and say good luck configuring and setting it up.

All of our solutions are pre-configured; ready to start reading the data signals, converting the protocols, and transmitting data to your destination in the message protocol and format you need.

CUSTOMER SERVICE is our Badge of Honor. Our onboarding and after the sale customer support is unmatched; all of our technicians are extremely experienced with industrial communications and industrial protocols.

Contact Us At:

MONICO INC.

18530 Klein Church Road

Spring, Texas 77379

Telephone: 281-350-8751

Email: sales@monicoinc.com

Find out more about Monico at www.monicoinc.com

Find out more about Monico at www.monicoinc.com

Monico, Inc. is not associated with or sponsored by Caterpillar® or Caterpillar® subsidiary Perkins - Cat® and Caterpillar® are registered trademarks of Caterpillar Inc.